- Autodesk free trial feature cam full#

- Autodesk free trial feature cam software#

- Autodesk free trial feature cam download#

But, I have full 3-D, 4th-axis, and turning. And, historically my maintenance has been a fuzz over $1500/yr.

M-CAM will let you tweak precious seconds out way easier than F-CAM.

Autodesk free trial feature cam software#

Even if you have to spend more time at the software tweaking? Run a lot of production? Big volumes where every second of cycle time counts. Having used both, my opinion is: in a shop that does a lot of "new" parts, F-CAM is the way to go. One of the biggest pluses M-CAM has over F-CAM? The tool-crib! F-CAM does some really stupid shit with their cribs. And, fine tuning that control is a little easier. M-CAM can give more infinite control over the actual tool-path. But, if you have a solid, it's just that much faster.Īnd if you are savvy with using different layers (think levels in M-CAM) you can keep a very organized, easy to look at, part file.ĭrawing (geometry creation) in F-CAM is way-way-way easier/faster. I have made some pretty dang complex stuff in F-CAM with simple geometry. This curve creating is essentially the same as chaining in M-CAM.

In MasterCAM, you "chain" your geometry to create tool-path. I will add a little bit to help the masses understand the difference between how tool-path is driven between the two. Unless someone is in the "know", I don't think the actual annual figures have been published yet for the various packages.You are correct on all counts Seymour! Unless someone is in the "know", I don't think the actual annual figures have been published yet for the various packages. Plain mill with feature recognition used to be in the 'hood of $4-5K - ish.ģD has different levels, ranging from 2K to 6K depending on what you need.Īll that however is now or soon to be out the window as FeatureCAM ( now AutoDesk product ) will be an annual subscription-only. Now to the OP, that is a difficult question. Well, you can just cut/paste a "feature" from another setup or another file or from a template, redefine the underlying curve and bang, you've just createdĪ brand new feature that inherits everything from the original, except it will be in a new location and of a completely different shape. Once the curve and then the toolpath is created, you can modify, move, or delete even the underlying geometry, and yet, your toolpath remainsĪs it was because it's based off of a curve ( actually you can use plain jane geometry as well but. You use the solids, surfaces etc to create curves, and then turn the curves into toolpaths ( Features ).

Autodesk free trial feature cam download#

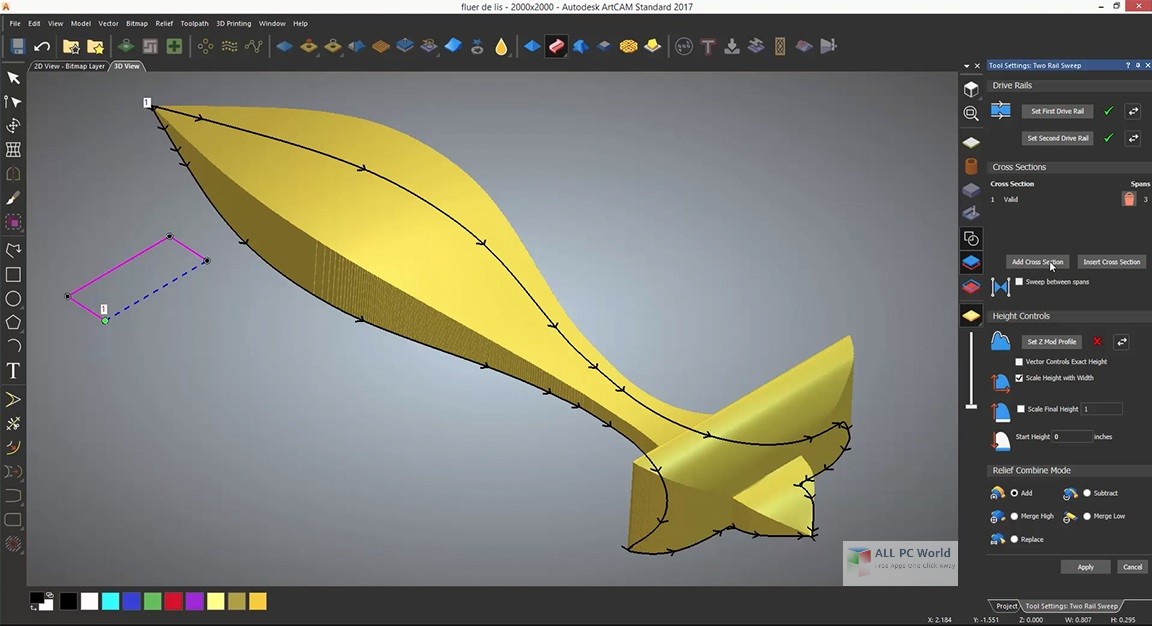

If you're interested in learning about FeatureCAM and exploring its capabilities, download theįree 30-day trial of FeatureCAM Standard before enrolling in this class! If you're interested in learning more about what FeatureCAM has to offer, visit our FeatureCAM website for more details.I really don't know what you're trying to say there AtomįC will work from either solids, surfaces, 2D or 3D geometry. Focusing on the workflow as opposed to specific tools and details in the software will ensure the smoothest possible transition between programming parts in this class, and confidently taking what you've learned into your own shop.ĭownload the free FeatureCAM Standard trial! While this class is meant to familiarize you with the details of programming parts in FeatureCAM Standard, the main objective of this class is to teach you the workflow of programming parts in FeatureCAM Standard. In this class, we will take a look at using FeatureCAM Standard to program a variety of milling parts, ranging from simple 2.5D parts, to more complex models incorporating organic surfaces with traditional 2.5D features. FeatureCAM automates your workflow from design to NC Code, reducing programming time and producing consistent results for CNC Milling, turning, and wire applications.

0 kommentar(er)

0 kommentar(er)